Journey Partner from Discover to Deployment

AVN is capable of commercial-scale production of new technologies for the market. We realize customer time and cost savings when we pair our skilled technician workforce and our powerful R&D technical team with our chemical manufacturing facilities.

All under one roof, AVN offers product development through laboratory research, pilot plant scale-up, and commercial scale manufacturing.

01

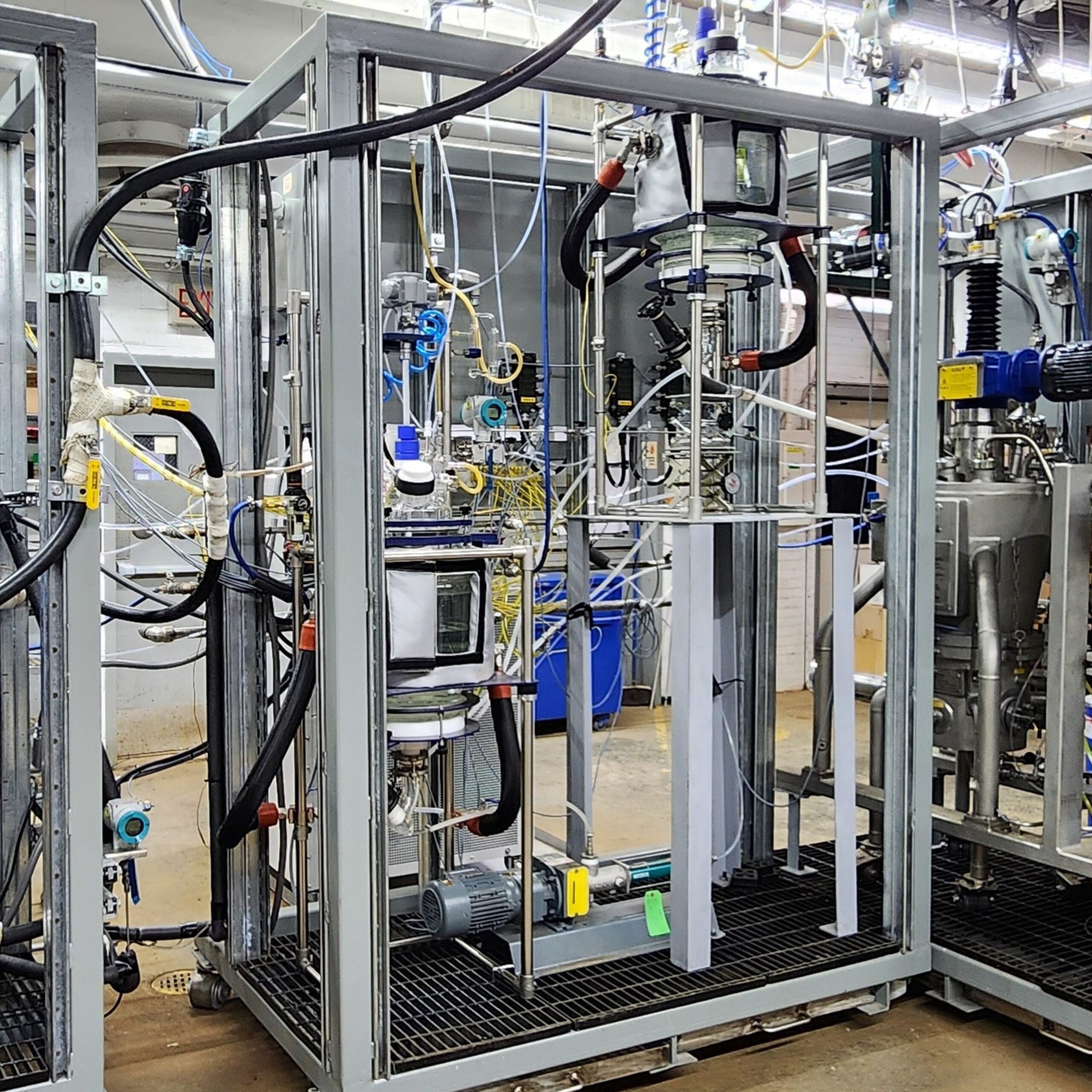

Manufacturing Capabilities

AVN prides itself on our staff’s experience across a broad range of chemistries and skillsets. We operate sophisticated facilities and can safely handle challenging and hazardous chemistries in a productive environment.

02

Batch & Continuous Operation

We are experienced in batch-to-continuous conversions of existing processes.

03

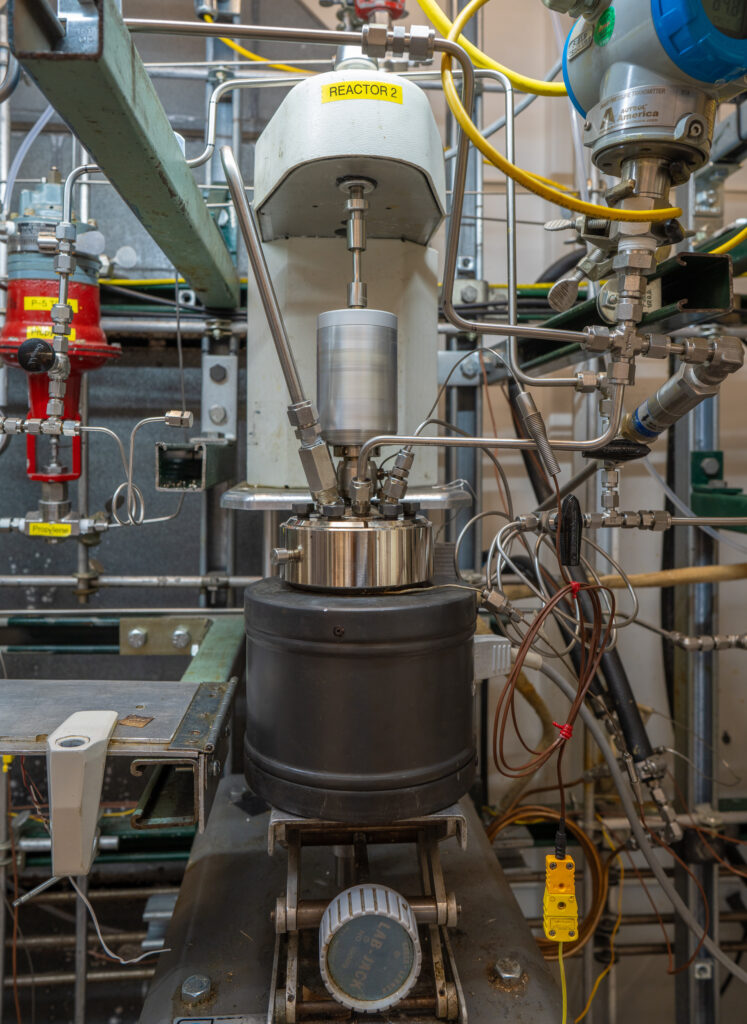

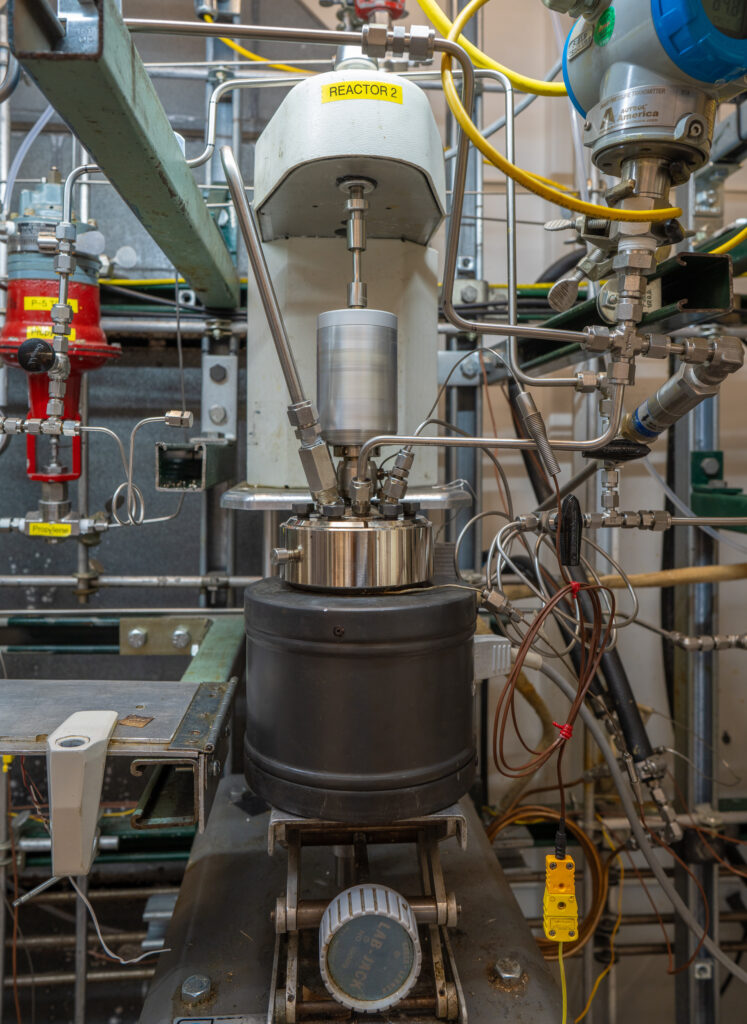

CTSR & Plug Flow Reactors

Reactors are available in a variety of sizes and materials of construction.

04

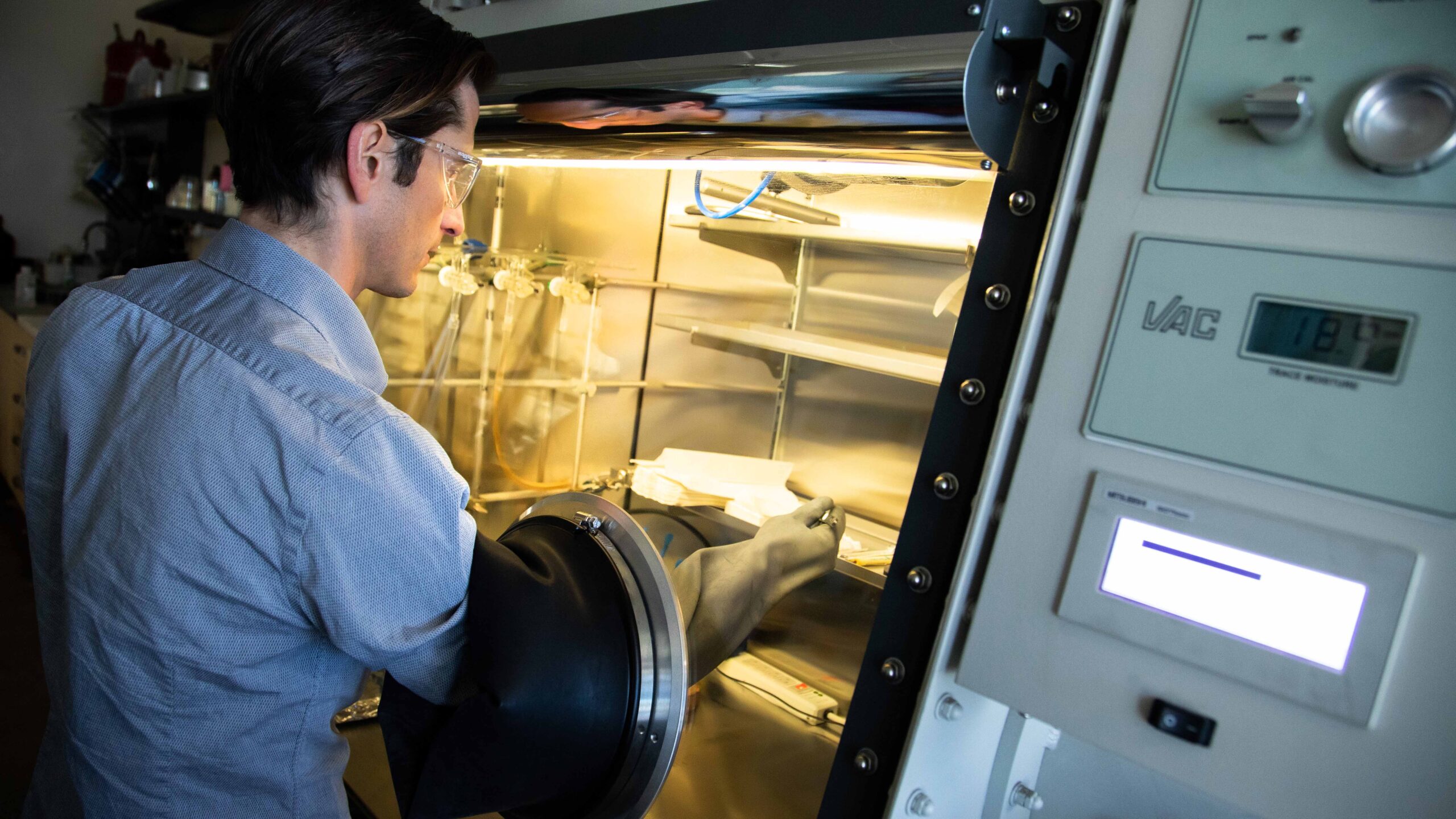

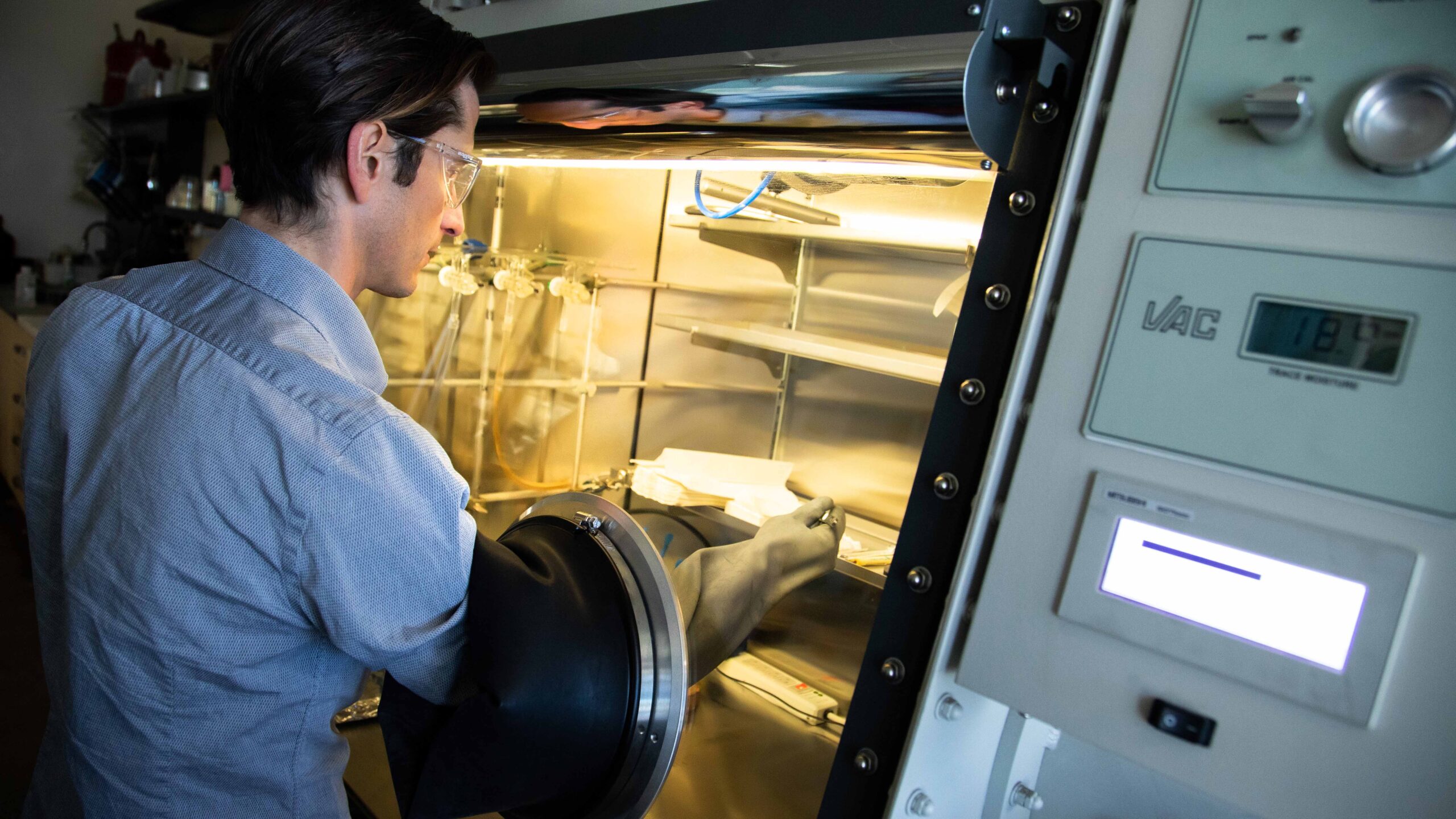

Heterogeneous and Homogeneous Catalysis Capabilities

AVN is equipped to support both heterogeneous and homogeneous catalytic processes, enabling flexible solutions for a wide range of chemical reactions.

05

Separations Expertise

We have particular strengths in distillation and crystallization.

06

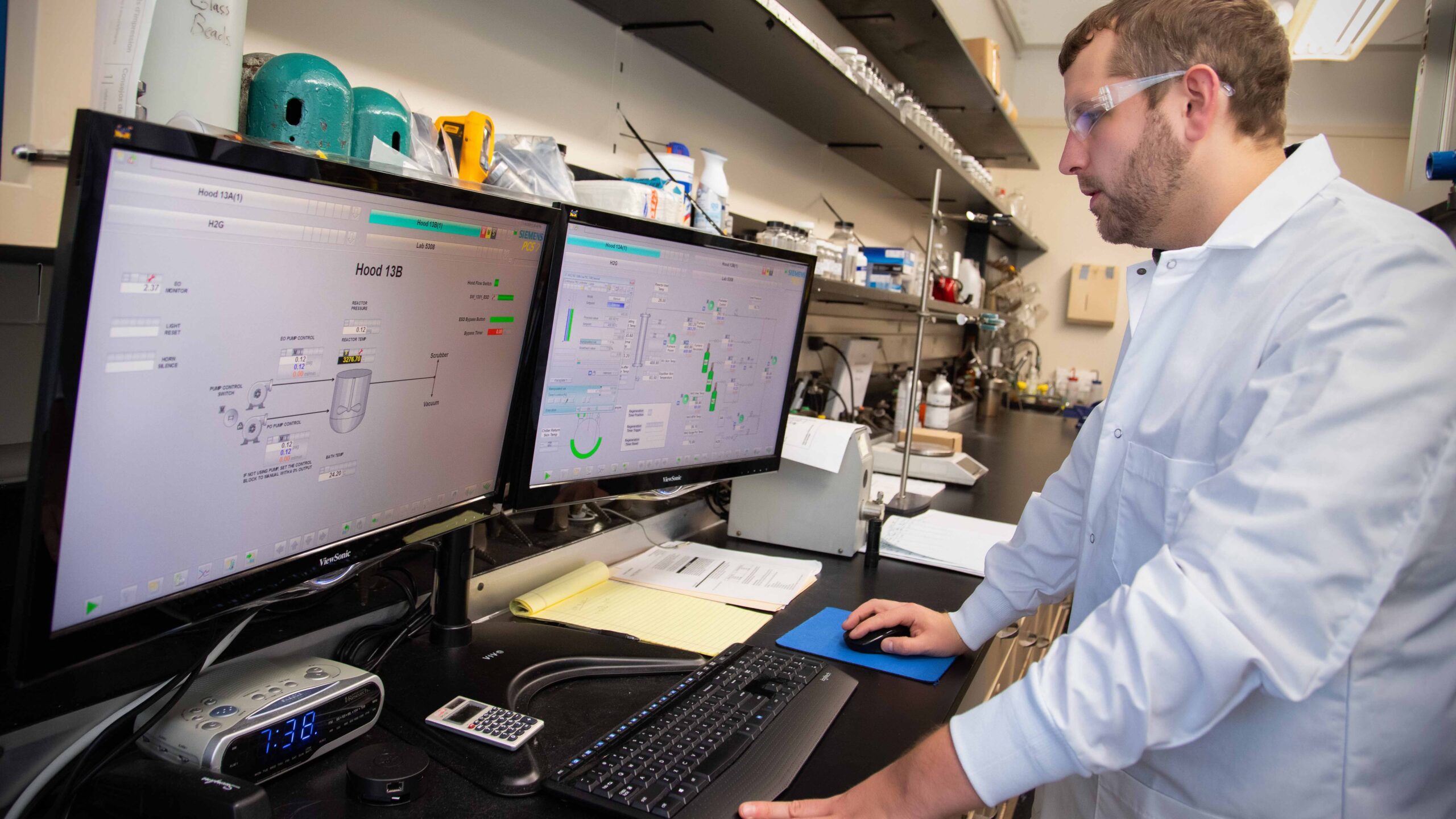

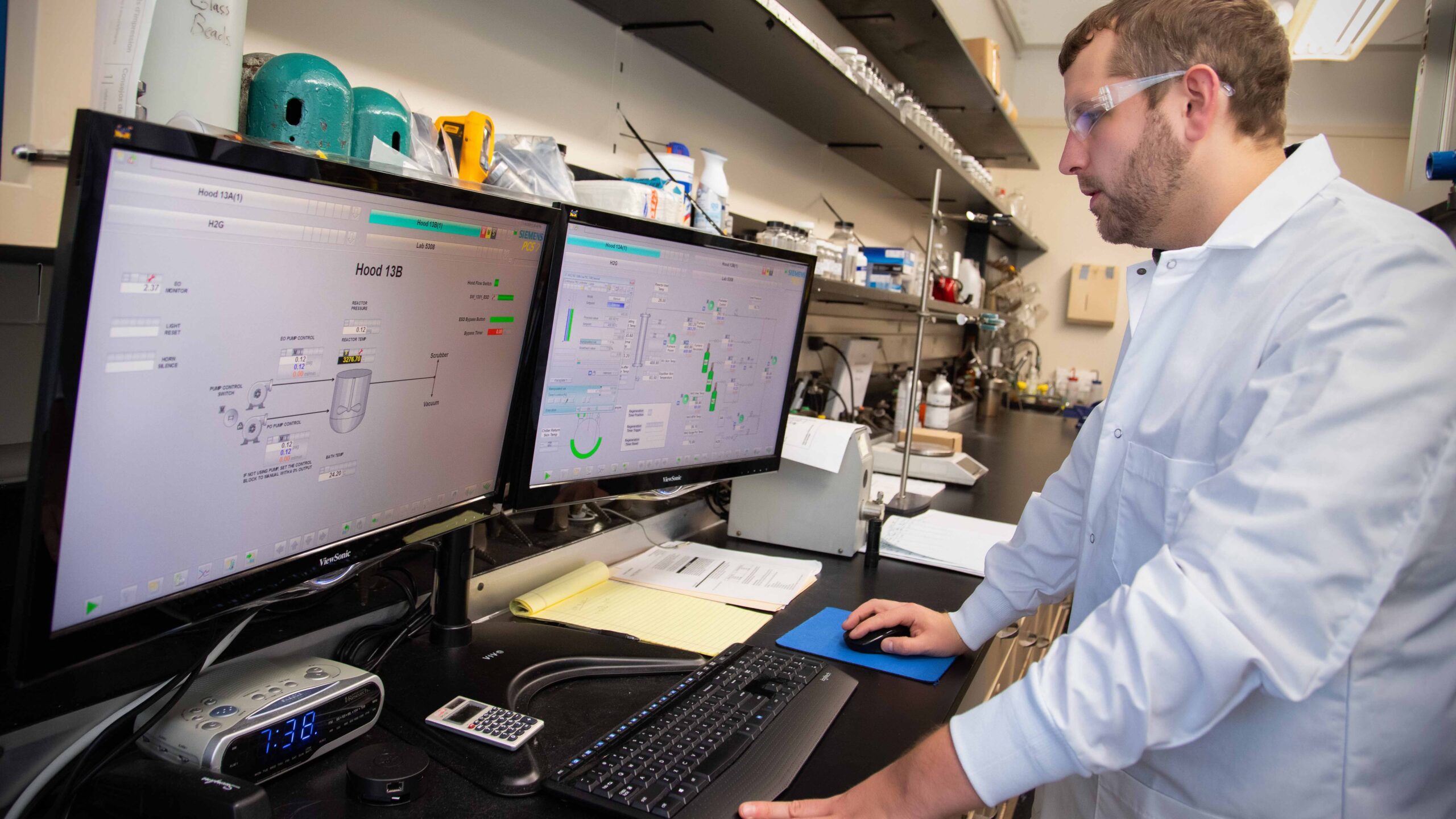

Fully Automated Process Capabilities Enabled by a Siemens Neo DCS

All processes are fully automated and controlled using a Siemens Neo Distributed Control System (DCS), ensuring high precision and safety.

07

Product Focus Areas:

• Specialty & custom chemicals

• Pharmaceutical ingredients

• Electronic materials

• Difficult chemistries where additional technical and safety knowledge is required

• New and novel chemistries

08

Technical and Analytical Support:

• On-site quality control lab for manufacturing support

• Research analytical lab for advanced support

• Backing of our full contract research organization if the need arises

Safety and Environmental Performance

AVN is committed to the safe and environmentally sound operation of our facilities. We maintain an excellent safety and compliance record and would be happy to share our latest performance metrics with you. Each project will undergo a review for process safety, personnel safety, industrial hygiene, and environmental compliance.

Let's Get In Touch

Contact Us

Locations and Business Units

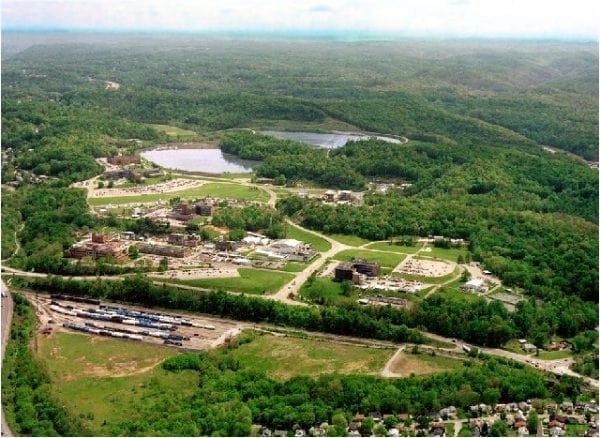

Corporate Headquarters,

Chemical Process Technologies,

Technical Engineering,

Specialty & Custom Chemicals Manufacturing

Physical Address

1740 Union Carbide Drive

South Charleston, WV

25303

Mailing Address

P. O. Box 8396

South Charleston, WV

25303

Locations and Business Units

Advanced Software Technologies

Physical Address

430 Drummond Street, Suite 2

Morgantown, WV

26505