Pilot Plant Operations & Maintenance Technician Intern

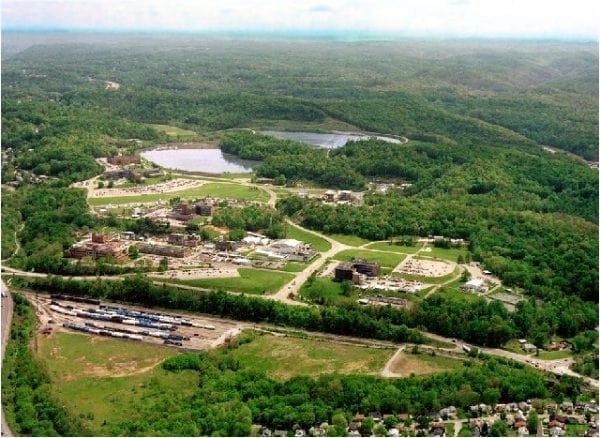

South Charleston, WV

About AVN

AVN is a strategic innovation partner providing deep, uncommon expertise and infrastructure to solve the most challenging problems of science and technology. With expertise in chemicals, energy, environmental, and advanced software technologies, AVN enables its partners to move ideas from conception to market with speed and efficiency.

Scope

Operation & Maintenance Technicians in AVN’s Pilot Plant Operations work within a team structure consisting of operators, engineers, and instrument/electrical technicians responsible for the safe construction, operation, and maintenance of small to intermediate-scale chemical facilities. These operations are typically built and operated for research purposes or the generation of market development samples. Pilot Plant Operations Technicians must carefully collect data for research and assist with process development while following safe work practices and being familiar with life-critical procedures similar to full-scale chemical operations.

The Operations Technician Intern works closely with full-time AVN Operations Technicians on projects in the pilot plant. The specific roles and responsibilities of the intern will depend on the project needs at the time but could include construction, operation, or decommissioning of pilot plant facilities. The role offers the intern the opportunity to learn many aspects of chemical operations, construction, and project implementation by working alongside AVN chemical operators, electricians, and engineers on active projects.

The nature of AVN’s Pilot Plant Operations is that technologies come and go as projects startup and shut down, similar to many research programs. The technologies are also varied as they come from many different types of companies and industries worldwide. Therefore, the operator must be flexible and capable of adapting to the changing work requirements with each new project.

Standard work hours for AVN chemical operators are 7:00 AM to 3:30 PM Monday – Friday. However, operations may require round-the-clock coverage, and the intern may work a rotating, 12-hour shift schedule alternating between day and night shifts. Interns may work some overtime depending on project needs. Internships are temporary, and the duration may vary depending on project needs and enrollment in an associate in applied science in process technology degree program or related field. However, typical interns will work 20 hours per week.

Major Responsibilities/Accountabilities

- Work safely with other technicians and safely handle flammable and hazardous chemicals following standard operating procedures.

- Install and checkout equipment, piping, tubing, and instrumentation under the guidance of experienced chemical operators and engineers.

- Perform basic field operations under the guidance of experienced technicians. May include startup and shutdown procedures, taking samples; running basic analytical tests; swapping raw material and product drums; performing cleanup and maintenance activities, and taking logbook notes.

- Basic sample collection.

- Assist with cleanup and disassembly of equipment under the guidance of an experienced operator. (Excludes first breaks on equipment in hazardous service).

- Interface with the computerized control systems and adjust chemical processes through these systems.

- Record detailed observations in logbooks under the supervision of experienced technicians; communicate regularly and clearly in verbal, written, or electronic form.

- Understand and follow life-critical procedures such as safe work permits, lockout/tag-out (LOTO) procedures, and standard operating procedures.

- Completes essential housekeeping responsibilities, painting, or other general upkeep and renewal activities.

Required Skills

- General knowledge of chemical industry practices, safe work habits, and an ability to work safely and maintain environmentally responsible work practices.

- The capability to follow and work under safe work permits, LOTOs, etc.; and the ability to take responsibility for one’s safety and the safety of co-workers and AVN clients.

- Basic math skills for routine calculations of raw material usage, feed rates, etc.

- A basic understanding of various chemical unit operations, equipment, controls, and piping systems.

- A general understanding of chemical processes and types of unit operations.

- Foundations for good note writing and general communication skills for effective research documentation and team understanding of operational conditions and issues.

- Capable of performing construction tasks under the guidance of experienced technicians. This can be an acquired skill with on-the-job training, but a mechanical aptitude for such work is required.

- Familiar with basic chemical analytical techniques such as gas chromatography, titration, etc.

- Ability to lift up to 50 lbs. intermittently throughout an 8 to 12-hour work shift; move construction materials; erect or relocate equipment; move drums; climb stairs and ladders; work at heights; etc.

- Ability to stand, walk, stoop, bend, and twist; work in tight or closed-in spaces; and wear all personal protective equipment, including respirators and chemical protective clothing.

- Proficient in Microsoft Office applications such as Word and Excel.

- Wear personal protective equipment (PPE) such as a hard hat, safety glasses, steel-toed shoes, gloves, hearing protection, fall protection, respirators, fire retardant clothing, etc. PPE will be provided as needed.

Required Education

- Currently enrolled in an associate’s in applied science in process technology degree program or related field.

Required Experience

- Experience in college-level process technology classes.

Position Location

South Charleston, WV

To Apply, use the following link: https://avncorp.applicantstack.com/x/detail/a2ok1ad2lc8b/aa0

All qualified applicants will receive consideration for employment without regard to race, color, religion, creed, age, national origin, ancestry, ethnicity, citizenship, sex, gender, sexual orientation, gender identity, pregnancy, familial status, disability status, genetic information, national origin, age, veteran status, or current or future service in the uniformed services, or any other characteristic protected by applicable local, state or federal law.

;)